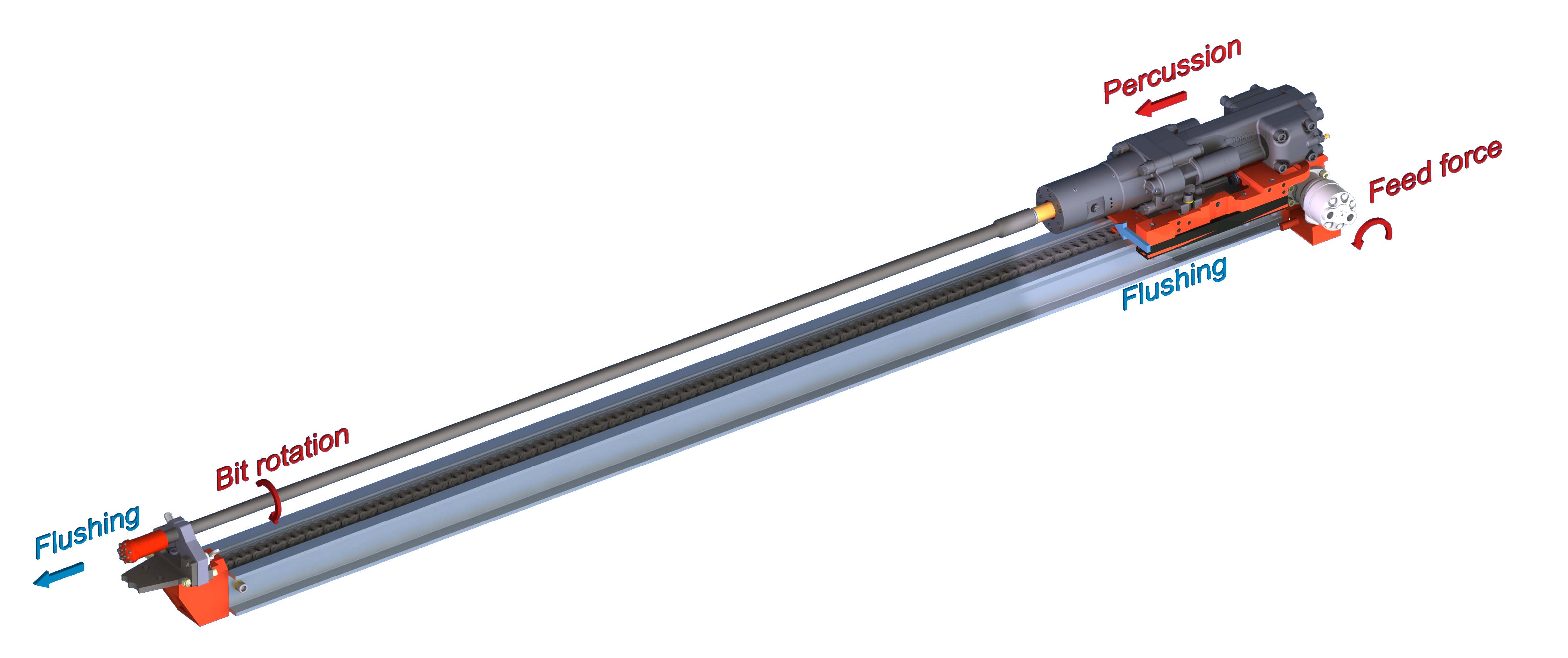

Doofor DFR8 is the most powerful model in the company’s hydraulic rock drill lineup. Designed for high-performance drilling in the most demanding environments, the Doofor DFR8 hydraulic rock drill offers a unique combination of impact power, modular construction, and protective features that extend the service life of the drill and drilling tools alike.

Engineered for high-impact productivity

The DFR8 is designed to meet the performance requirements of large-scale drilling operations, particularly in quarry and production drilling applications involving larger and deeper blast holes. In underground use, the rock drill is suitable for both production drilling and tunneling.

The model is available in two power versions: 21kW and 25kW, providing customers with a versatile solution for both new drilling platforms and retrofit installations.

Key features for durability and tool protection

In addition to high impact energy, the DFR8 features several technical protections that safeguard both the drill and the drill string during heavy-duty operations.

A hydraulic dampening system comes as standard, reducing the reverse shock loads from the drill rod to the machine itself. This not only protects internal components but also contributes to better thread retention and lower heat generation.

The DFR8 is also equipped with a built-in reverse percussion system, which helps to release stuck drill bits or loosen tightly coupled rods. This feature can be set to passive mode, depending on operational needs.

Modular design for harsh conditions

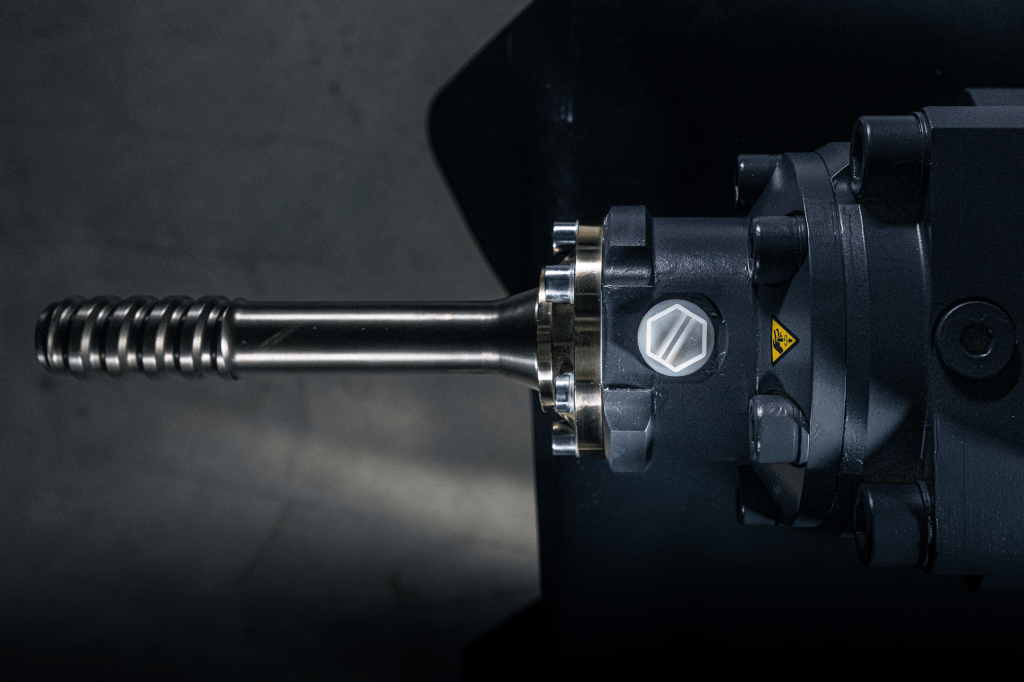

Like other Doofor models, the DFR8 is based on a modular structure that brings added benefits for field use. By grouping multiple core functions within a single unit, the number of pressurized flange joints is minimized, thereby reducing the risk of oil leaks and simplifying maintenance. One example of user-friendliness is the ease of on-site seal replacement.

The Doofor DFR8 is utilizing air oil mist lubrication, while additional grease nipples are an option. Using air oil mist cools the rock drill while eliminating the need for daily grease lubrication.

Designed to meet real customer needs

The Doofor DFR8 rock drill was developed specifically to meet the needs of customers requiring higher torque and impact energy in tough geological conditions. The rock drill offers good penetration speeds while hole depth increases or rock formations change during operation.

All design elements are based on extensive in-house testing and field experience, making the DFR8 a reliable tool for professionals seeking performance without compromise.

Benefits of the DFR8

• High impact energy for demanding drilling operations

• Modular, leak-resistant construction for long-term durability

• Standard hydraulic cushioning for component protection

• Built-in reverse percussion system for rod handling and bit release

• Two power versions available for wide application compatibility

• Oil-air mist lubrication for simultaneous cooling and maintenance simplicity

Find out more

Looking for a high-performance rock drill that meets the toughest drilling requirements? Discover more about the DFR8 and integration options for your equipment platform.